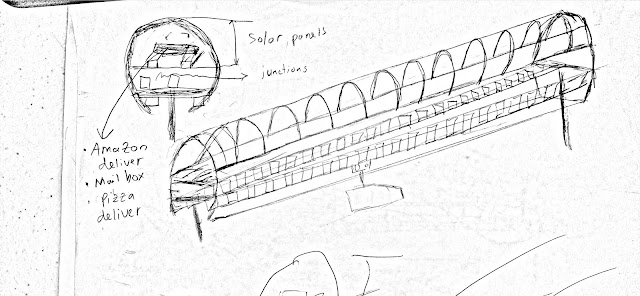

Week 9: SolidWorks Design

This week, I started designing on SolidWorks. My team and I was unsure about how the design should look like; therefore, the design that I have was not our final design. This week, I am going to talk with other full scales team to discuss more about the design. Since my team is going to use sheet metals to design the racking system for solar panel, we have to follow some rules. For example, in Figure 1, the distance from outside mold line to the bottom of the cutout should be equal to 2.5* Material Thickness + Bend Radius. When using a punch press tool we should never use a tool who’s diameter is less than that of the material’s thickness etc. Figure 1: Design with sheet metals has to follow some rules Figure 2: Use sheet metals to connect trusses together Besides, I figured out an easy way to connect sheet metal truss together by using bent sheet metal pieces.